Dry Gas Seals - Specialist Training

Understanding their design, installation and operation to improve reliability.

Updating your skills

Developing your Team's skills

To operate industrial plants both safely and efficiently, you need highly skilled, well-trained and knowledgeable personnel.

With the introduction of new technology, production processes, the need for increased plant availability, and the global awareness of manufacturing processes being sustainable, it is important to ensure that these skills are kept up-to-date.

AESSEAL® provides specialist training courses that are specifically designed to help your staff develop their knowledge and understanding of mechanical seals, dry gas seals and support systems

These courses are designed for companies that are aiming to:

• Understand the technology associated with Dry Gas Seals

• Maximize rotating equipment reliability

• Helps to identify and prevent Dry Gas Seal operational issues

• Improve site efficiency

Dry Gas Seals

The Need for Specialist Training

Understand

To understand the technology associated with Dry Gas Seals

Maximise reliability

Maximise the reliability of rotating equipment

Trouble Shoot

Help identify and prevent Dry Gas Seal operational issues

Efficiency

Improve the efficiency of your site

What does the course cover?

The Design and Fundamentals of Dry Gas Seals – covering the history and development of dry gas seals, it will describe the different types and variations of seal. Dry Gas Seal operating principles will be discussed covering topics such as face groove design, the balance of forces and the effects of ‘slow roll’.

- Separation seals will be discussed as well as the different elements of dry gas seals such as the stator, rotor and secondary seals.

- The training will give an overview of the benefits of wet versus dry gas seals, discussing the considerations when considering retrofits and give an overview on API 692.

- How to Improve Reliability – covering the different failure modes and their indicators.

- Dry Gas Seal Assembly and Pre-Installation Checks – see how dry gas seals are assembled and the basic principle of seal installation care including the required dimensional checks.

- Dry Gas Seal Removal and Installation – covering a description of the equipment required to install a sealand how to the commission a Dry Gas Seal.

- Dry Gas Seal Storage and Transportation – this section will discuss how to properly transport and store a Dry Gas Seal.

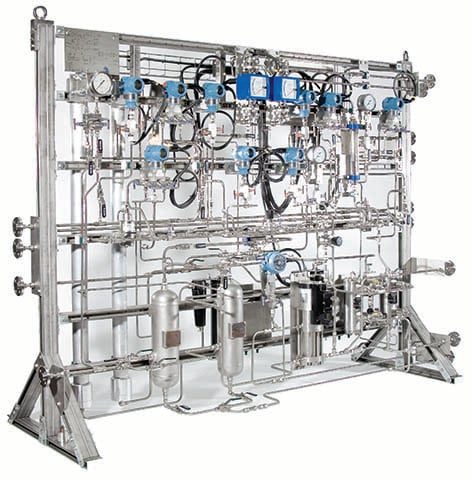

- Dry Gas Seal Support Systems – this section will describe the design, operation and maintenance of a suitable system covering the requirements for filters, boosters and heaters

The courses can be customised to your specific needs and involve both classroom and hands-on time.

Design and Fundamentals

A typical training course takes 2 days and can be provided either at the AESSEAL® Global Technology Centre, or at the customers site. A minimum of 3 delegates are required and it is recommended that the course is limited to a maximum of 12. Attendees will be provided with all course training materials and a certificate of completion will be given at the end of the training.

Prices for the training are available on request

The Trainers

Dr. Chris Carmody Phd, MSc Beng (Hons)

Chris started his career as a maintenance engineer in the chemical and process industry and joined AESSEAL® as the company’s first full time seal designer and development engineer. Chris went on to academia for a bachelors degree, a masters of science in structural integrity and doctoral degree on the fluid structure interaction of bioprosthetic heart valves.

He re-joined industry as a Consulting engineer and worked on many prestigious projects such as the A380 Airbus, the award winning Falkirk wheel and the new Wembley stadium. Chris returned to AESSEAL® and took up the position of special products manager

where he is responsible for development of high integrity sealing projects including dry gas seals. He now has 25 years of experience in the design of mechanical seals and is a named inventor on many of AESSEAL® product designs. In addition to his responsibilities at AESSEAL® he also sits on several bodies including the API 692 Compressor Dry Gas Seal Committee.

Alasdair Conn BSc (Hons)

Alasdair has worked with Dry Gas Seals for nearly 10 years carrying out a variety of functions and roles. Following 9 years with the UK Ministry of Defence, where he completed a 3 year Mechanical Engineering Apprenticeship, he joined a global mechanical seal manufacturer as a technician building and testing wet and dry gas seals before progressing into the Dry Gas Seal engineering department as an application engineer.

Upon completion of his degree, he was promoted to Engineering Project Manager where he led a small team primarily focused on providing Dry Gas Seal Retrofit solutions to customers worldwide. He subsequently moved into a Commercial Project Manager role where he led commercial alignment initiatives and hosted technical seminars focusing on Dry Gas Seals. He also led a high volume Service Centre for a leading rotating equipment provider before joining the AESSEAL® team as Global Technical Specialist – Dry Gas Seals.